More than just statics: what does a life cycle analysis do in structural design? Interview with René Zemp, Head of Structural Engineering

Building today means building for tomorrow. The structure is one of the biggest levers for reducing CO2 in structural engineering. But how can I, as a building owner, decide which structural variant is more sustainable? What are the concrete benefits of an ecological balance sheet - beyond certificates and checklists? And how can I, as an architectural firm, use well-founded CO2 data as an argument in competitions?

One person who has dealt with these questions is René Zemp. He heads the structural engineering department at Basler & Hofmann in Lucerne and is a member of an interdisciplinary team of civil engineers and sustainability experts at Basler & Hofmann who have pooled their expertise in a life cycle assessment tool. The tool can be used to create ecological balance sheets - also known as life cycle analyses (LCAs) - for entire buildings, individual components and technical systems. An interview about planning and building in the circular economy.

René, what data is the ecological balance sheet tool you developed based on?

René: We are basically guided by the Swiss guidelines and standards, specifically the SIA 390/1 "Climate path - partial greenhouse gas and energy balance of buildings" and SIA 2032:2020 "Embodied energy - life cycle assessment for the construction of buildings" standards. We obtain the life cycle assessment data from the KBOB (Coordination Conference of the Construction and Real Estate Bodies of Public Building Owners). Depending on the project, we sometimes "go beyond" the system limits of the Swiss standards if we believe this makes sense for a fair comparison.

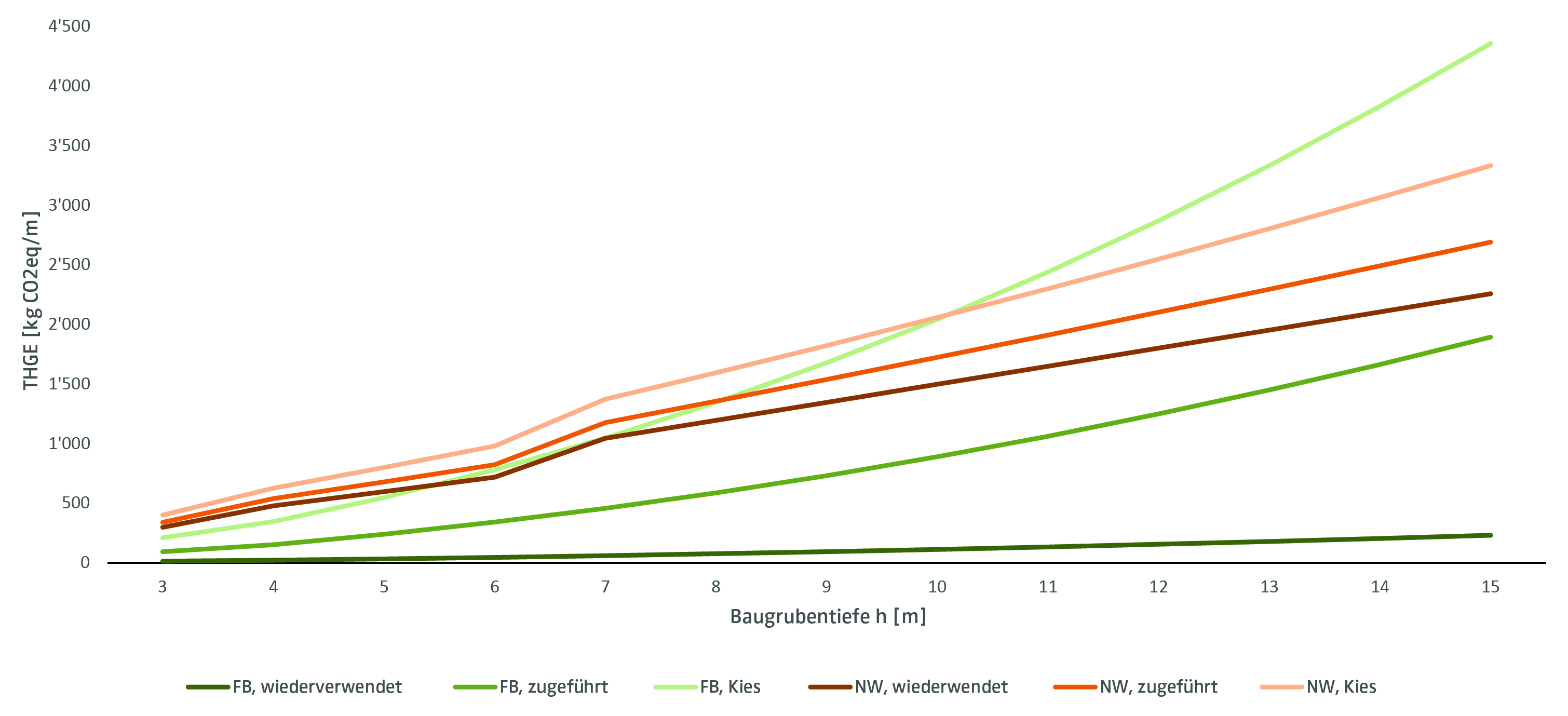

Do you have an example? When do you go beyond the system limits of the SIA standards?

René: According to the SIA, the excavation of an excavation pit and its removal, as well as any transportation of the backfill material to the construction site, are not necessarily accounted for. In the case of new construction, however, the excavation pit can make up a relatively high proportion of the ecological balance sheet. If we want to compare two possible retaining wall structures, such as a sheet pile wall and a soil-nailed wall, in terms of their environmental indicators, it is important to carry out a life cycle assessment to the required depth.

How do you actually use the life cycle assessment tool in concept designs?

René: We use the tool both in our own projects and to independently review the designs of external competitions and project teams. Ideally, the tool is used in the earliest possible phases of a construction project. This is when the client has the greatest leverage in terms of sustainability. We need it more and more often in architectural competitions to compare different variants together with the architecture team and propose a project that is as sustainable as possible. This was one of the reasons why we won the competition for the new State Archives of the Canton of St. Gallen.

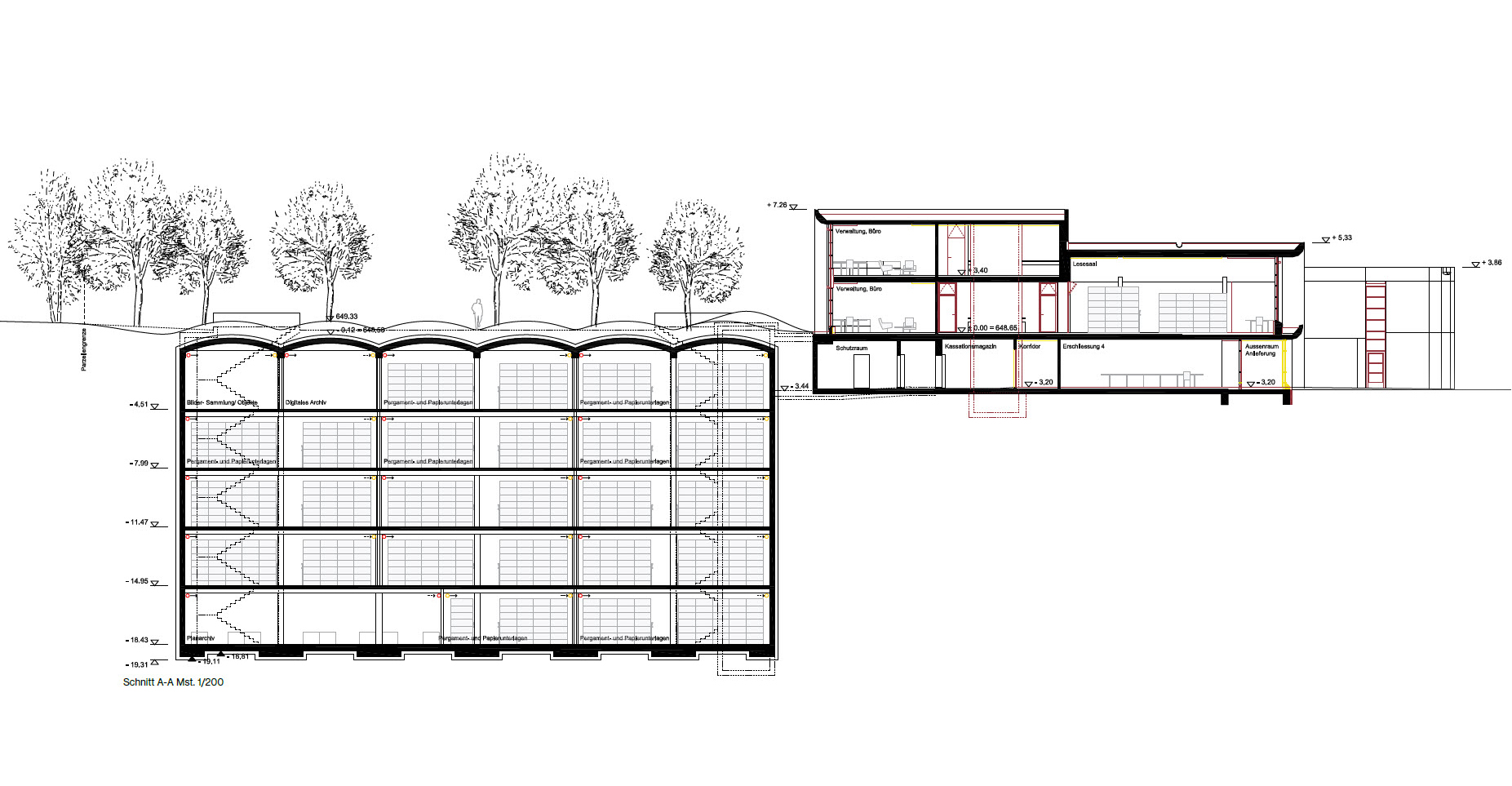

To what extent was the ecological balance sheet a decisive factor in this architectural competition?

René: In the case of the State Archives in St. Gallen, it was stipulated that the CO2 emissions per square meter and year must not exceed 9.0 kgCO2eq/a, given the fact that the new underground storage building must be designed as a protective structure in order to withstand a nuclear attack according to TWK 2017. Specifically, this results in loads in the range of 150kN/m2 instead of the usual 2-3kN/m2. In order to keep the structure as efficient and resource-saving as possible, we designed the ceiling of the new storage wing as a vaulted ceiling. Inside the magazine, we proposed a narrow column grid adapted to the archive cabinets, which, together with the beams, made a very material-saving ceiling only 14 cm thick possible. We also proposed constructing the magazine using a cut-and-cover method, which would not require any complex excavations. With the ecological balance sheet of the structure, we were able to show the client that we could create a very sustainable structure in this way.

What has been your biggest "aha moment" so far in the life cycle assessment of structures?

René: One example is definitely the ecological balance sheet that we did for the competition we won for the extension of the school in Root. For the construction of the new gymnasium, which is spanned by trusses and thus supports the loads of the two floors above, we compared three variants for the ceiling system: a conventional flat ceiling made of reinforced concrete, a Holorib ceiling and a box girder ceiling made of wood. As expected, the wooden ceiling clearly has the smallestCO2 footprint. What surprised the client and the project team was that, contrary to popular belief that timber construction is always more expensive than reinforced concrete, the timber ceiling was also able to beat the other two variants in terms of construction costs. The reason for this lies in the steel framework, which has to bear more load in the concrete variants and therefore has to be more massive.

Is wood always the most sustainable choice?

René: It usually makes sense to construct the large volumes, such as the ceilings, in wood. That's where you have the greatest leverage. Individual elements without a large volume, such as beams or supports, can also be made from a different material. Our approach is: we work with an open-material approach and use any material where it makes ecological and economic sense.

Assuming the decision is made in favor of concrete, what levers do you have to plan more sustainably with concrete?

René: We currently have an exciting project in the infrastructure sector. We were commissioned by the client to plan a substation conventionally in concrete. The client has now changed project management and decided that the project should be completely revised taking sustainability principles into account. On the one hand, we have now investigated which parts of the structure we can build from wood. Secondly, we examined where we could replace the conventional concrete with more ecological types of concrete that meet the requirements of the structure. In addition to the life cycle assessment, this requires our expertise in concrete technology.

What are the challenges with the new, more ecological types of concrete?

René: It is very easy to select more ecological types of concrete in the ecological balance sheet tool and find out how muchCO2 emissions can be saved compared to conventional concrete. However, the structure must then also be durable. Certain more ecological types of concrete have a lower resistance to carbonation, which means that the reinforcing steel corrodes more quickly. And with some of the new types of concrete, it must be noted that they harden more slowly, i.e. they have longer stripping times, which can have an impact on the construction process. As civil engineers, we have to use our specialist knowledge to reconcile all project requirements.

Apart from the choice of materials: What can be used to optimize the sustainability of a structure?

René: Basically, the choice of materials comes at the end of a cascading approach with a focus on sustainability. You should first consider whether an existing building can be repurposed or extended or whether re-use components can be used. If a new building is being constructed, simple, compact building shapes, continuous load transfer and small spans are ideal in terms of sustainability. If the loads are not transferred via continuous supports, supports and correspondingly more material are required. The same applies to large spans: The more spans, the thicker and more material-intensive the ceiling. However, these simple basic principles are only compatible with the client's spatial requirements and the architectural design in very few cases. In the interests of sustainability in particular, the design process therefore requires greater dialog between the client, architect and civil engineer.

It is not uncommon to hear and read that those who build sustainably pay more. Do you agree?

René: No, not always. We have been able to show in various competitions that maintaining a building is both more ecological and cheaper than building a new replacement. And in the competitions for the Root school complex, the timber ceiling system was even able to beat the reinforced concrete version in terms of construction costs. And in these examples, we are only comparing the construction costs. They do not include the follow-up costs that an additional ton of CO2 has for us as a society as a whole. I would therefore like to encourage building owners to ask themselves the question of value instead of cost: How much are we willing to pay for one ton less CO2?

In a previous article, we put together five arguments as to how building owners can benefit from an ecological balance sheet of their structure and used a warehouse building to show how an ecological balance sheet can support the decision on variants in an early planning phase. Read article now